Optical Metrology

Group Coordinator

Member of the academic staff

Members of the Academic Staff

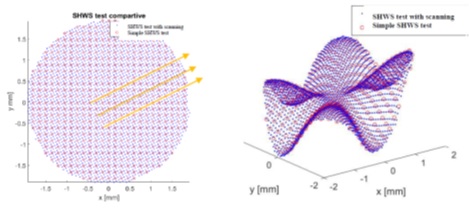

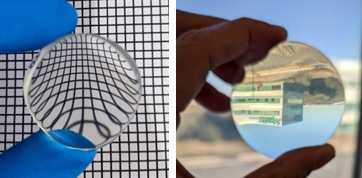

The members of the Optical Metrology Group share a common interest in using the tools of optics to solve practical and novel problems that allow us to design, fabricate and evaluate both qualitatively and quantitatively conventional optical surfaces with symmetry of revolution such as simple lenses, conical mirrors, solar concentrators as well as non-conventional optical surfaces without symmetry of revolution, such as arbitrary shaped surfaces, ophthalmic lenses, wavefront corrector plates, arbitrary-shaped reflecting surfaces, among others.

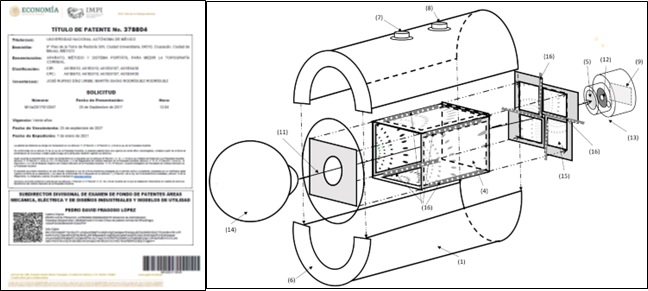

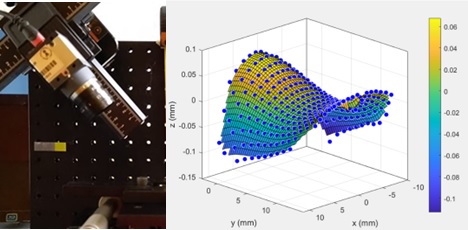

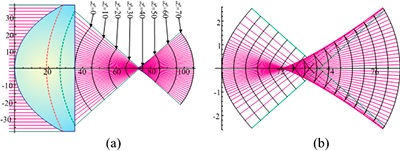

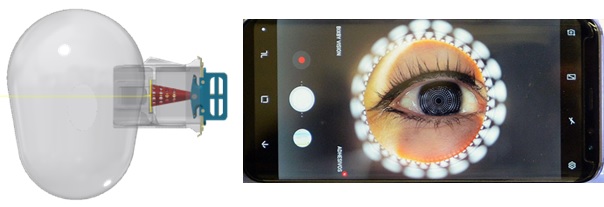

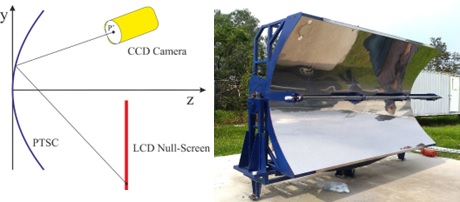

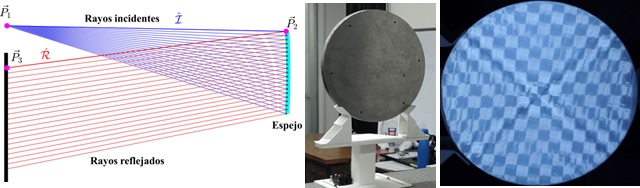

In the line of optical testing by both refraction and reflection, the null-screen method has been developed to rapidly measure convex and concave optical surfaces. These techniques have been applied to spherical, aspherical, off-axis and non-revolution symmetric surfaces. Direct applications of this optical deflectometry technique have direct applications in areas of national interest such as health, energy and human security. In particular, for the measurement of corneal topology, the characterization of solar concentrators and the characterization of the surfaces that form the basic components of a seismic isolator of the friction pendulum type.

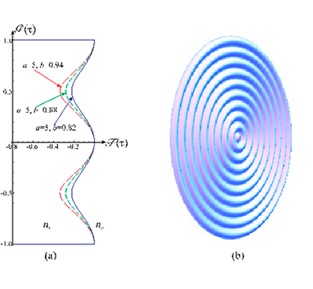

Also, in this same line, we are studying optical systems using birefringent materials, the design of off-axis systems of the Schiefspiegler type (with off-axis conical components) and the analysis of caustics for the characterization of optical systems and to reduce aberrations such as spherical aberration and third-order astigmatism.

In the optical design line, we have worked on the design and construction of several optical systems, a portable overhead projector, two corneal topographers with conical screens, one fixed and the other based on a smartphone, and a corneal topographer with cylindrical screens.

- Optical testing

- Optical metrology

- Optical deflectometry

- Optical design

- Light scattering

- Light polarization

- Optical surface fabrication

- DGAPA-PAPIIT 2023 No. IT103623: “Evaluation of aspheric and fast free-form surfaces with and without revolution symmetry by optical deflectometry”.

- DGAPA-PAPIIT 2021 No. IT100321: “Evaluation of freeform optical surfaces fabricated by additive manufacturing”.

- DGAPA-PAPIIT 2023 No. IT103823: “Optical metrology of freeform surfaces”.

Graduate

- Dra. Dulce María González-Utrera

Dr. Efrén Santamaria-Juárez

- Dr. Martín Isaías Rodríguez-Rodríguez

- Dra. María del Carmen López-Bautista

- M. en A. Edith Guadalupe Vázquez-Navarrete

- Dr. Gabriel Castillo-Santiago

- Dr. Jesús Alberto Del Olmo-Márquez

- Dr. Oliver Huerta-Carranza

- M. en I. Ulises Edmundo Espinoza-Nava

Doctoral

- Irán Robles-Gutiérrez

- Martín Jiménez-Rodríguez

- Ismael Velázquez-Gómez

- Osvaldo Ponce-Hernández

Master’s

- Francisco Javier Bautista-Clemente

- Marco Montes-Valles

Undergraduate

- Ana Elizabeth Hernández-Guerrero

- José Antonio Lechuga-Núñez

- Jesús Alberto Aguirre-Caro

- Luis Ángel Pantoja-Arredondo

- Tyra Delgadillo-Mendoza

- Edgar Isaí Olvera-López

- Alexander Perez-Degante

- María Guadalupe Bribiescas-Chávez

- Vanessa Vázquez-Pérez

The Optical Metrology Group has four laboratory spaces, with five optical tables, some of them of the floating type. It has several lasers of different types and wavelengths, CMOS or CCD cameras, power meters, motors, and controllers for precision positioning of mechanical components, lenses, prisms, beam splitters, mounts, among others. It also has a laboratory at the Applied Research and Technology Unit (UNITA), in Apodaca, Nuevo Leon, Mexico.

It has state-of-the-art computers for simulations, analysis, and automatic control of experiments; Zemax license for optical design; high precision spherometer; Abbe type refractometer.